Operator

Specification:

| Testing Scope | 550*500mm |

| Component size | 0201 and above chip components

|

| Testing Type | Automatic |

| Recording Type | Automatic |

| Quality Tracking | Yes |

Operator |

0 |

| System Safety | User permission setting |

Evaluation Method |

Software evaluation |

Testing speed |

Averaging: 1 second |

Automated testing |

Automated testing (Coordinate,LCR) |

Multiple screen sharing |

Portable screen monitor |

Testing pass rate |

98% |

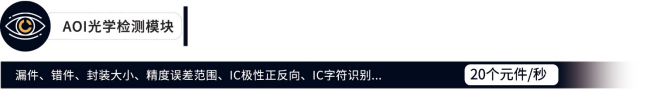

Optical algorithm |

AI+OCR |

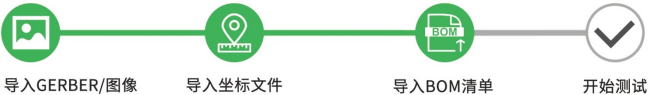

Manufacturing procedure |

AI Recognition, compatible with different file formats, import with one click |

Result display |

Display components within a list and give an overall view. |

Supporting components |

Above 0201 ounce SMT components |

| Testing Speed | Visual inspection 0.05 second/component; LCR 3 second/component |

| Testing Precision | 0.01% |

| Machine Size | 850(L)x1172(W)1851(H) mm |

Product Characteristics:

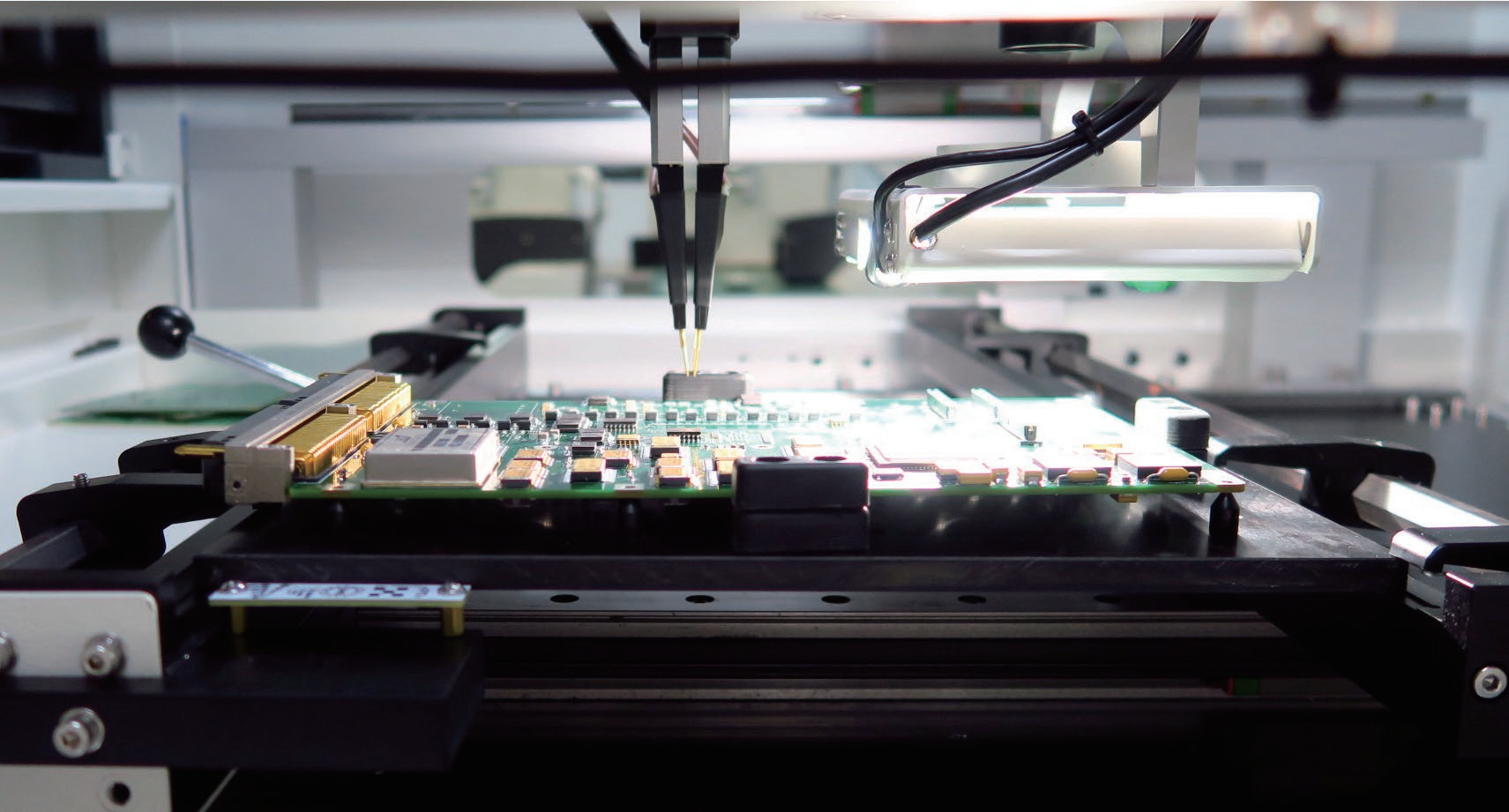

Testing the SMD components of the PCB board through scanning, intelligently auto-crops the PCB scan image, import PCB components and BOM bills. The software will proceed with an intelligent synthesis of PCB images, coordinates and BOM, along with global coordinate calibration.

For silk screen printing parts, AI algorithms combine with OCR to enable batch rapid detection.

For capacitors and inductors without silkscreen markings, it utilizes an automated flying probe with a LCR meter to perform gripping and measurement. It intelligently optimizes the probe path, automatically captures component values, and compares them against specifications.

|  |  |

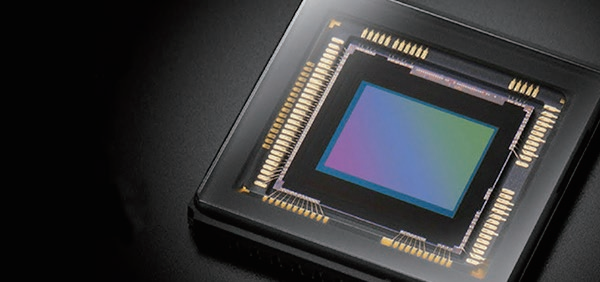

CMOS camera Fast image scanning, automatic determination of resistance values, characters, polarity | 500X software simple operation, own tutorial, wide compatibility, user-defined format | LCR Bridge Compatible with different brands of LCR bridge,test capacitance, resistance, inductance, etc |