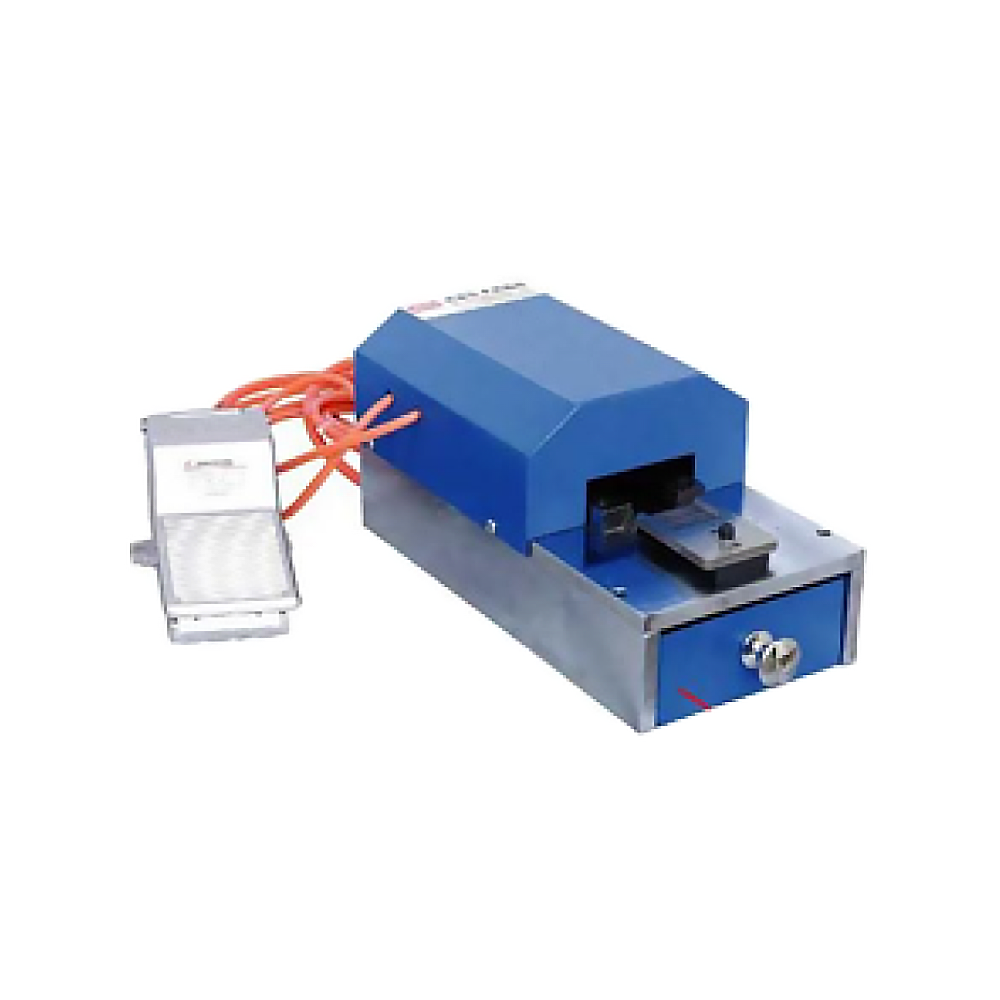

Control System:

Uses a branded PLC and a Chinese touch screen interface. All settings are directly set on the touch screen, and the working process is displayed in real time. I/O points can be checked for easy maintenance. The system features accurate control (time control precise to 0.01s), strong anti-interference ability, good stability, and error operation alarm. The vacuum part uses a low-noise oil vacuum pump, and the sealing part uses double air cylinder.

Manual / Automatic Function:

Automatic double-pedal: The required packaging parameters are preset. Step on the first pedal to confirm that the product and the bag opening are flat. Step on the second pedal to automatically complete the whole packaging process according to the program, doubling the packaging speed.

Manual triple-pedal: Step on the first pedal to confirm that the product and the bag opening are flat. Step on the second pedal to start vacuuming. When the vacuum level meets the requirement by observation, step on the third pedal to start the program and automatically complete the whole packaging process.

Mode Selection:

According to packaging needs, multiple modes such as vacuum packaging and sealing can be selected separately, reducing wear of parts and extending the machine’s service life.

Vacuum Mode: Vacuum → Sealing

Sealing Mode: Sealing only

Optional Triple Protection for Heating Part:

The heating part uses a non-contact solid-state relay control to prevent the relay contacts from sticking due to excessive current. To avoid overheating caused by interference or improper parameter settings, a parameter upper limit (2.5s) is set in the software.

To prevent continuous heating caused by software failure, a precision time relay (2s) is added as secondary protection to ensure the heating time will not exceed due to interference or incorrect settings.

An external temperature controller monitors the sealing temperature of the heating element in real time. When the temperature reaches the alarm value set on the controller, it immediately cuts off the heating transformer power and gives an alarm signal, ensuring that even if the solid-state relay or secondary time relay fails, the heating power will still be cut off to prevent continuous heating.