一、Overview实物图

二、Features特色

极速AI一键编程,快速测试

RapidAIoneclickprogrammingandquicktesting

全球首款智能人机交互(语音识别)AOI

Theworld'sfirstintelligentHuman-ComputerInteraction(voicerecognition)

行业误报最少检测设备之一

Oneoftheindustry'slowestfalsealarmdetectiondevices

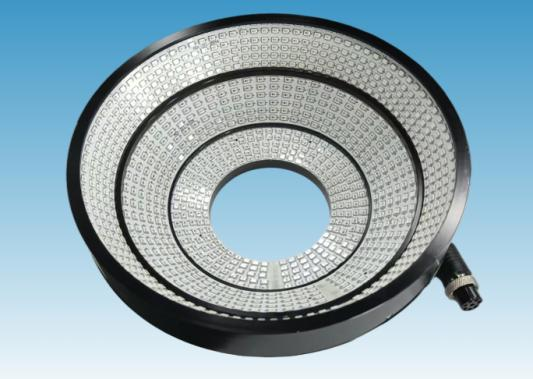

三、Precision optical imaging精密的光学影像

工业相机高速取像,抓拍高清

Industrialcameraforhigh-speed imagingandcapturing high-definitionphotos.

三色塔型光源RGB三色LED与多角度塔状组合设计,能准确反映出物体表面坡度层次信息

Tri-colortower-shapedlightsource:RGBtri-color LEDscombinedwithamulti-angletowerdesign,accuratelyreflectingthesurfacegradient informationofobjects.

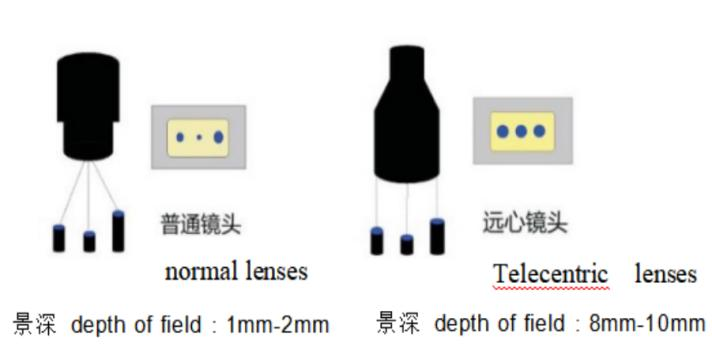

双远心镜头:拍摄图象无视差,有效避免反光干扰,最大程度降低高元件,解决景深问题

TelecentricLens:Capturesimageswithoutparallax,effectivelyavoidsglareinterference,minimizes theimpactofhighcomponents,andresolvesdepthoffieldissues.

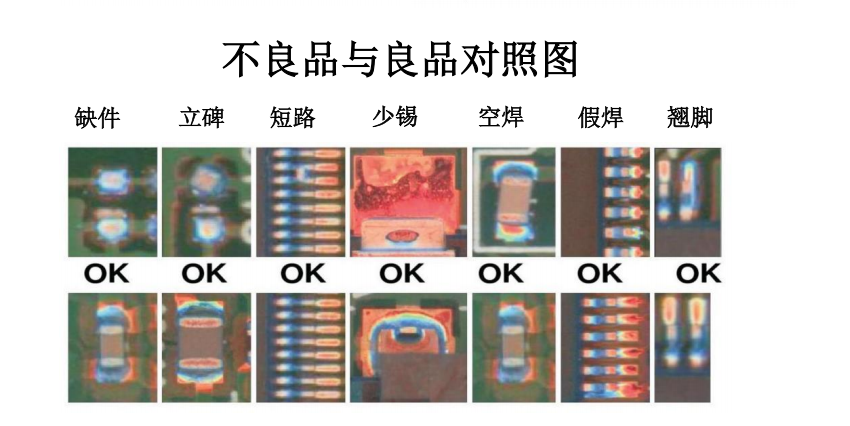

四、实例

五、Datasheet规格表

型号Model T3 pro | |

轨道与PCB尺寸Conveyor&PCB Size | |

PCB尺寸Dimension | 0x50mm-470x330mm |

PCB厚度Thickness | 0.5mm -5mm |

PCB元件高度Height | Top 25mm:Bottom 110mm |

PCB翘曲高度Warp | ±3mm |

工艺边PCB Transfer Height | 2.5mm |

光学参数Optical Parameter | |

摄像头Camera Spec | 5MP |

分辨率Resolution | 15μm |

光学镜头Optical Lens | 双远心光学镜头Telecentric Optical Lens |

光源Light-Source | 多光谱超高速RGB六通道光源Multis pectral Super speed RGB Light Source |

速度Speed | 0.238 sec/FOV |

硬件配置Hardware | |

X/Y平台重复定位精度Table Positioning Accuracy | +/-0.01mm |

X/Y平台移动速度Table Speed | 900mm/s |

PCB夹持PCB Clambing | 自动夹持By Auto |

驱动Driver | 松下交流伺服电机+研磨丝杆AC Servo Motor+Screwing Shaft |

设备外观尺寸Dimension(W*D*H) | 860X 1040X 1318mm |

重量Weight(KG) | 345KG |

电源及功率Power Supply | AC 220V 50/60Hz 1KW |

操作系统Operating System | Win 10企业版Enterprise Edition |

显示器Display | 23.8”LCD Monitor |

独立显卡Discrete graphics | 英伟达NVIDIA 3060 |

可检测类型Inspection Category | |

元件检查Component Inspection | 缺件,反转,偏移,极性,错件,破损,AI元件弯脚,PCB板异物,金手指 沾锡,溢胶,整板侦测多件。 Missing,Rolling,Shifting,Polarity Error,Wrong Part,Damaged, Bended,PCB Abnormal,Residua,Glue Overflow |

焊接检查Solder Inspection | 锡多锡少,侧立,立碑,锡桥,虚焊,翘脚,锡珠,波峰焊后焊接(含插件) Excess Solder,Insufficient Solder,Bridging,Lifting,Solder Balls,Soldering Abnormal |

特殊检测项目Special Inspection Items | 可检查锡膏制程,红胶制程及波峰焊后的PCB上元件的装配焊接质量,3D可 测元件高度,引脚翘起虚焊,做高度检测 Can Check Solder Paste and Epoxy Glue Process,Soldering Quality; Checking Floating Components and Cold Joint by 3D |

软件系统Software | |

检测算法Inspection Method | AI算法、特征矢量分析法、丝印OCV算法 AI Algorithm&The Eigenvector Analysis &OCV Silkscreen Algorithm |

多角度检测Inspection Angle Area | 0-360°,检测精度Accuracy=1° |

标记功能Marking Function | PCB整板Mark,拼板Mark,坏板Mark等 One Board Marking &Multi-pieces Board Marking &Bad Marking,etc. |

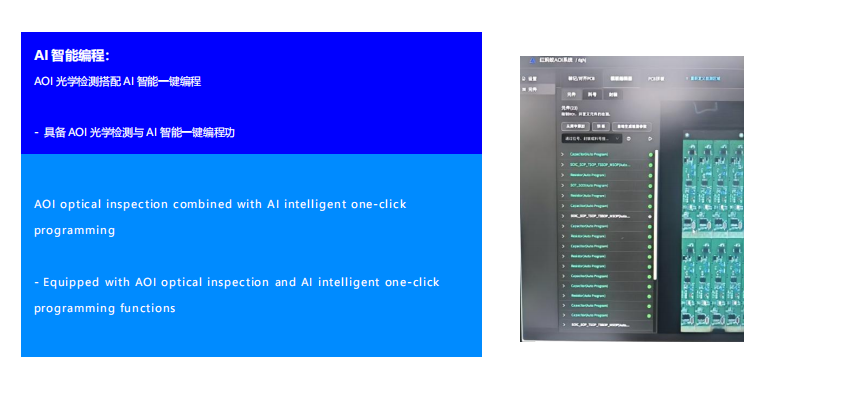

编程模式Programming Mode | 1.CAD坐标自动导入CAD Coordinate Loading 2. 自动索引元件库Component Database Auto-index 3.软件自动AI建模Auto-programming by Intelligent Software |

远程控制Remote Control | 通过网络实现:离线编程;远程实时调试;远程查看/远程控制操作设备等 Network Monitoring:Offline Debugging,Online Monitoring & Manipulating,Remote Realized Examing |

人机交互系统Human-Computer Interaction system | 通过语音指令控制软件操作机器,解放双手提升效率 Improve efficiency and free up hands by controlling software operations on machines through voice commands |

记录功能Data Recording | 自动生成统计分析(SPC)及数据报表 Auto-generated Statistical Process Controlling Data(SPC)&Report |

选项Option | |